A new publication titled “The Chemical and Physical Origin of Incineration Ash Reactivity in Cementitious Systems” was published in Resources, Conservation and Recycling in October 2021.

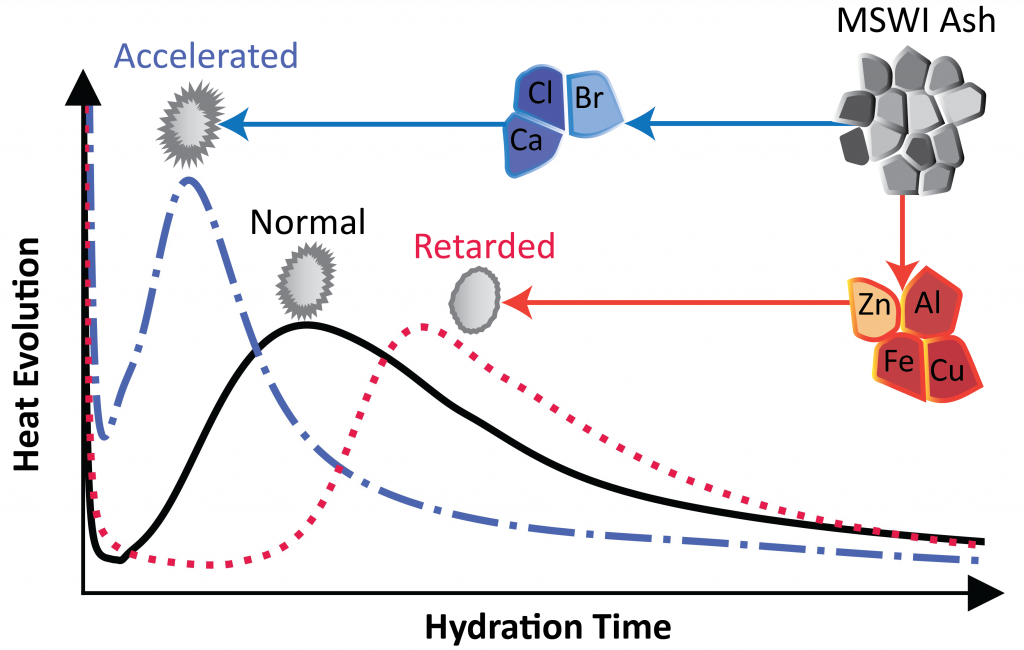

Incorporating industrial byproducts and waste in concrete is the key to reducing landfill usage as well as lowering the environmental footprint of cement industry. An emerging industrial byproduct which can partly replace cement is the Municipal Solid Waste Incinerator Ash (MSWI ash: residue that is left after incineration of municipal solid waste in a Waste-to-Energy facility). These ashes are predominantly calcium-rich; however, they also contain additional elements whose speciation is not known. These elements can significantly alter the hydration characteristics of a cementitious system. Our initial foray into cementitious matrices including these ashes, reveals that these ashes can accelerate as well as retard cement hydration. Specifically, Pb, Br, S, Ca, and Cl appear to accelerate cement hydration, whereas Cu, Fe, Al, Ti, Si, K, Zn, and Sr appear to retard cement hydration. Changes in hydration characteristics can have a strong bearing on the physical characteristics of cementitious systems incorporating incineration ashes. Thus, to selectively screen ashes that synergistically enhance the physical characteristics, we introduce a novel “Incineration Ash Coefficient (IAC),” which shows a strong correlation with the compressive strength (R2=0.79) of cement-ash binary mixtures.

This is the first article from our group’s Ph.D. candidate Vikram Kumar. Congratulations Vikram!

The article can be accessed here.